Concept: External focussing system for film-cameras, based on a UV-laser.

Reading Time: 5 minutesIn 2014, after working more and more frequently on film productions with my self-built camera drones and stabilization systems, I was surprised to discover that the professional camera systems did not have a well-functioning autofocus. Larger film cameras were focused manually, and focusing on fast-moving subjects was a major challenge. Even the frequently used DSLRs only utilized a contrast autofocus and constantly pumped back and forth between focus planes, which made the resulting footage virtually unusable.

How to measure distances precisely?

Pondering how to solve this problem technically, I researched various ways of reliably and quickly measuring the distance to a moving object. I realized that a laser rangefinder probably had the greatest potential for developing an external focussing system for film cameras. The plan to create a prototype was made, but the necessary sensor had to meet a number of requirements:

- Sampling frequency greater than 30 hertz

- Low power consumption for mobile use

- Use of a non-visible spectrum of light

- Eye safety classification: Class 1M

- Available for civil applications

- Small package size

I finally found a company in South Africa whose product met all the requirements – the SF30C Time-of-Flight laser from Lightware.

Challenges to tackle!

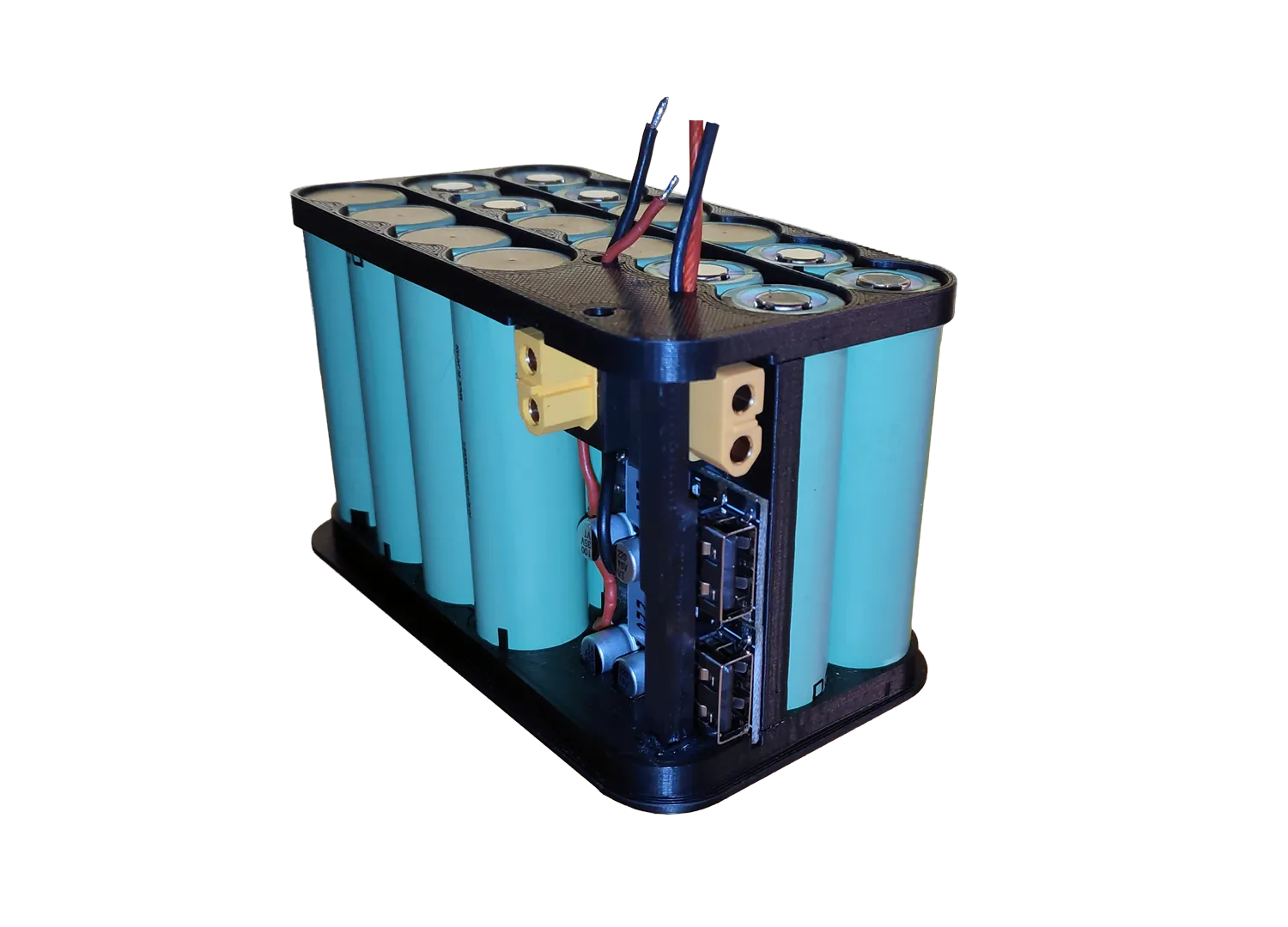

Well, to get the project off the ground, I had no choice but to immerse myself in microcontroller programming. So, a few Arduinos were ordered, along with an LCD, several rotary encoders, push-buttons and other small items. In the following months, I focused on the logic of programming, the necessary electronic infrastructure for the controller to be created, the optical properties of lenses, and the mathematical foundations for a functioning code.

Here is a series of thoughts and realizations that came into my head during the initial phase of development for a camera-mounted prototype:

- A fast and powerful actuator is required to confidently rotate the focus ring of even larger lenses.

- The actuator must be as small and light as possible so that it can be operated on a gimbal, for example.

- The focus ring on most lenses behaves logarithmically in relation to the distance to be focused on.

- Each lens has specific characteristics that require its own profile and so a calibration routine.

- Mathematical interpolation is required to focus on distances between calibration measurement points.

- For some lenses, a typ of backlash compensation must be implemented on the software side.

- The further away an object is, the more difficult it is to reliably hit it with a single laser beam.

Solutions:

In the absence of a professional motor for remote focus control, I decided to use a powerful brushless servo for my proof of concept. The only disadvantage of this approach is the noise associated with its use. Assuming my experiment is successful, professional lens control motors would be used for future applications.

The specific characteristics of each lens are recorded during a calibration routine that captures approximately 15 measurements for the distances between the minimum focus distance and infinity focus. All values between the measured distances are interpolated by the algorithm; a higher density of measured values is particularly advantageous in the close-up range. Here, small changes make a big difference in the quality of the focus.

Regarding the backlash compensation, a user-defined value determines the angle in degrees required to reverse the focussing direction, while maintaining high precision for the focus, even with photo-lenses that utilize a slip-clutch with backlash.

If the preliminary tests are successful, there is the option of initiating the development of a multi-beam laser. The expanded capabilities of such a sensor would enable the use of more complex algorithms and significantly increase the usability of the system.

Prototype testing:

The first tests were conducted with the sensor mounted on the hot shoe of a Nikon D-5300. A 50 mm lens with a wide aperture of F-2.2 was used. At a distance of 1.5 m, this corresponds to a depth of field of approximately 0.08 m – which is quite low. The initial results were promising: Despite using a lens with a slip-clutch and only a rough calibration, my system worked faster and more precise than the camera’s built-in contrast autofocus. Another advantage that became clear: The focus works in any lighting situation.

Single-beam vs Multi-beam vs Lidar:

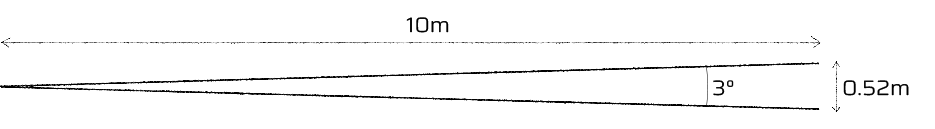

As for the challenge of tracking a distant target with a single-beam laser: During the first test, the external focusing system performed well, but it became apparent that it was difficult to reliably hit a target the further it moved away from the camera. At a distance of 10m, a 3-degree change in the cameras pan axis resulted in a 0.5m shift in the focus point. This corresponds approximately to the width of a human being.

Deviation when the cameras pan axis is shifted by 3°

Furthermore, the limitation to a single beam restricts the image composition, as it is only possible to focus on subjects in the center of the image, just as if the camera had only one focus point. To exploit the full potential of the concept, the use of a multi-beam laser would therefore be essential. Procuring such a sensor proved difficult, as it would first have to be developed by Lightware, which would have involved high costs.

The following considerations dealt with the use of a lidar sensor, as this would be able to “scan” a larger area in front of the camera, thereby solving many of the problems listed above at a stroke. However, in 2014, this type of sensor was still very expensive and difficult for private individuals with a small budget to obtain.

Years later, the validity of my concept was confirmed: In 2021, the chinese company DJI utilized exactly this kind of approach and released a product – the DJI Focus Pro:

The original idea behind Exofocus

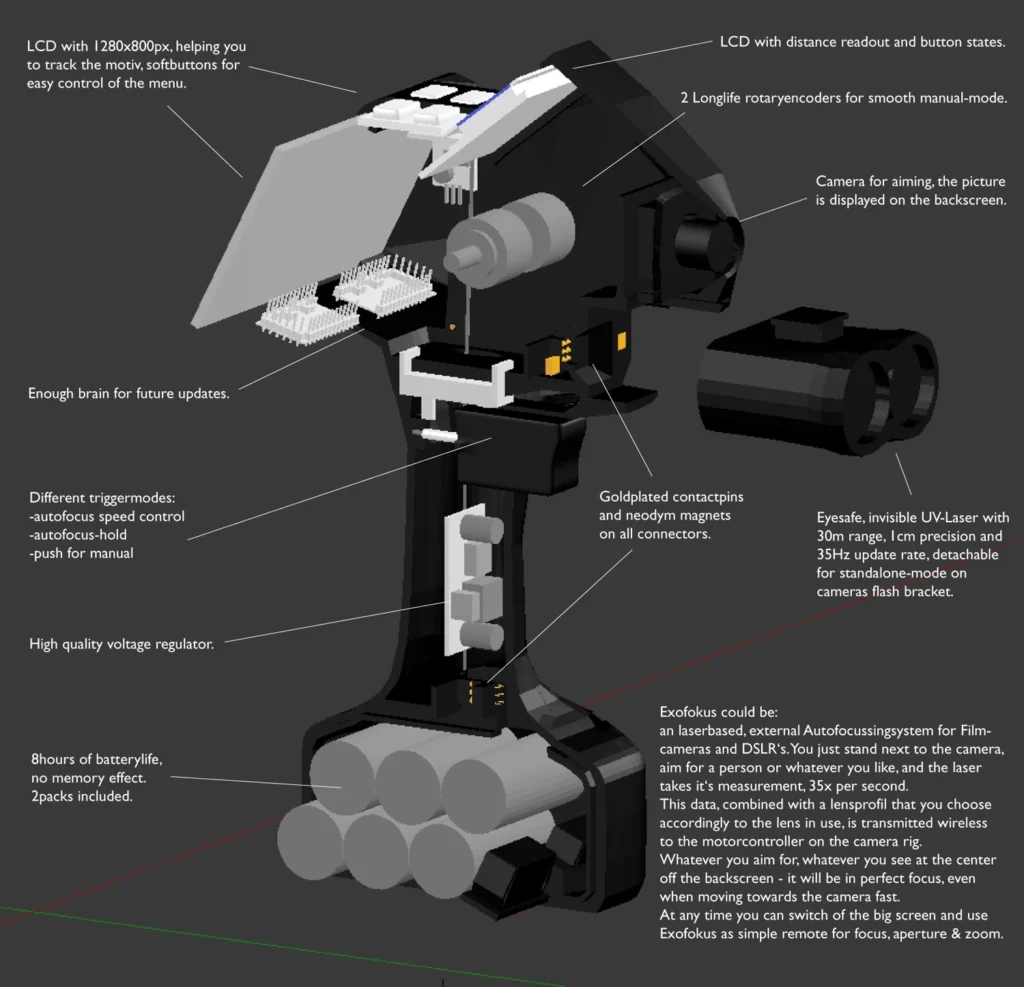

Incidentally, the original idea I had for this project went one step further. The sensor was only to be mounted directly on the camera for stand-alone operation. The entire product was to be based on a pistol-like device that could be used to simply aim at the object to be focused on while standing near the camera.

Even more challenging from a technical perspective – it would require precise detection of the “pistol’s” position in relation to the camera. Back than I considered two approaches feasible:

- The use of computer vision to detect three LEDs integrated on both sides of the pistol. Since their geometry relative to each other is known, a suitable algorithm could be used to calculate the distance and angle of the pistol in relation to the filming camera.

- The use of three radar beacons, which are triggered sequentially and integrated into the housing of the pistol. Based on trilateration using the flight time of each beacon signal, their alignment in relation to the film camera could be calculated.

In manual mode, it could be used as a universal lens controller, just like numerous devices that have been used by focus pullers in the professional film industry for decades. Here you see one of the first drafts:

Towards the end of 2014…

…my situation did not allow me to continue this project with the necessary resources. My freelance work took up a lot of time, and I couldn’t afford the investments needed for further development. So the hardware disappeared into a drawer, the project files into an archive folder, and only the rangefinder continued to be used – as a precise laser altimeter on one of my multicopters.