Concept: Manufacture of composite battery housings for electric longboards

Reading Time: 3 minutesWhen designing an electric longboard, I was faced with the question of how best to accommodate the necessary lithium-ion batteries. Strong vibrations, changing temperatures, mechanical stress, and water pose a challenge for the design of the battery housing. After careful consideration, I decided to make a positive mold out of wood and use a vacuum molding process to produce a fiberglass housing that should be able to withstand the expected operating conditions.

Considerations

The material for a positive mold must meet certain requirements in order to be suitable for vacuum forming: It should have good machinability, high dimensional stability, and a non-absorbent surface. Molds produced with an FDM printer are suitable, for example, but wood is also a material that, due to its availability and mechanical properties, is suitable for mold production. The wide variety of profiled timber available in DIY stores provides an ideal basis for creating even complex geometries, without the need for time-consuming mechanical finishing.

Column of air

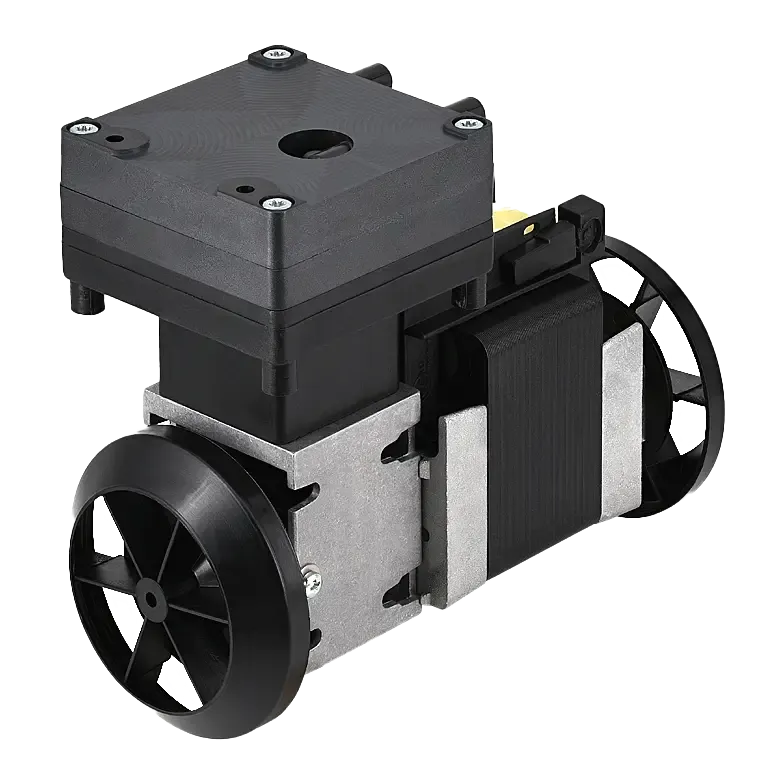

To create the vacuum, I used an eccentric diaphragm pump from Schwarzer Precision. It is capable of generating a vacuum of up to 810 mbar. At this value, atmospheric pressure exerts a force of approximately 8 newtons per square centimeter of the mold surface—more than enough to reliably press the fiberglass fabric onto the mold. It’s absolutely amazing what forces can be unleashed with the help of the column of air above our heads.

The positive mold

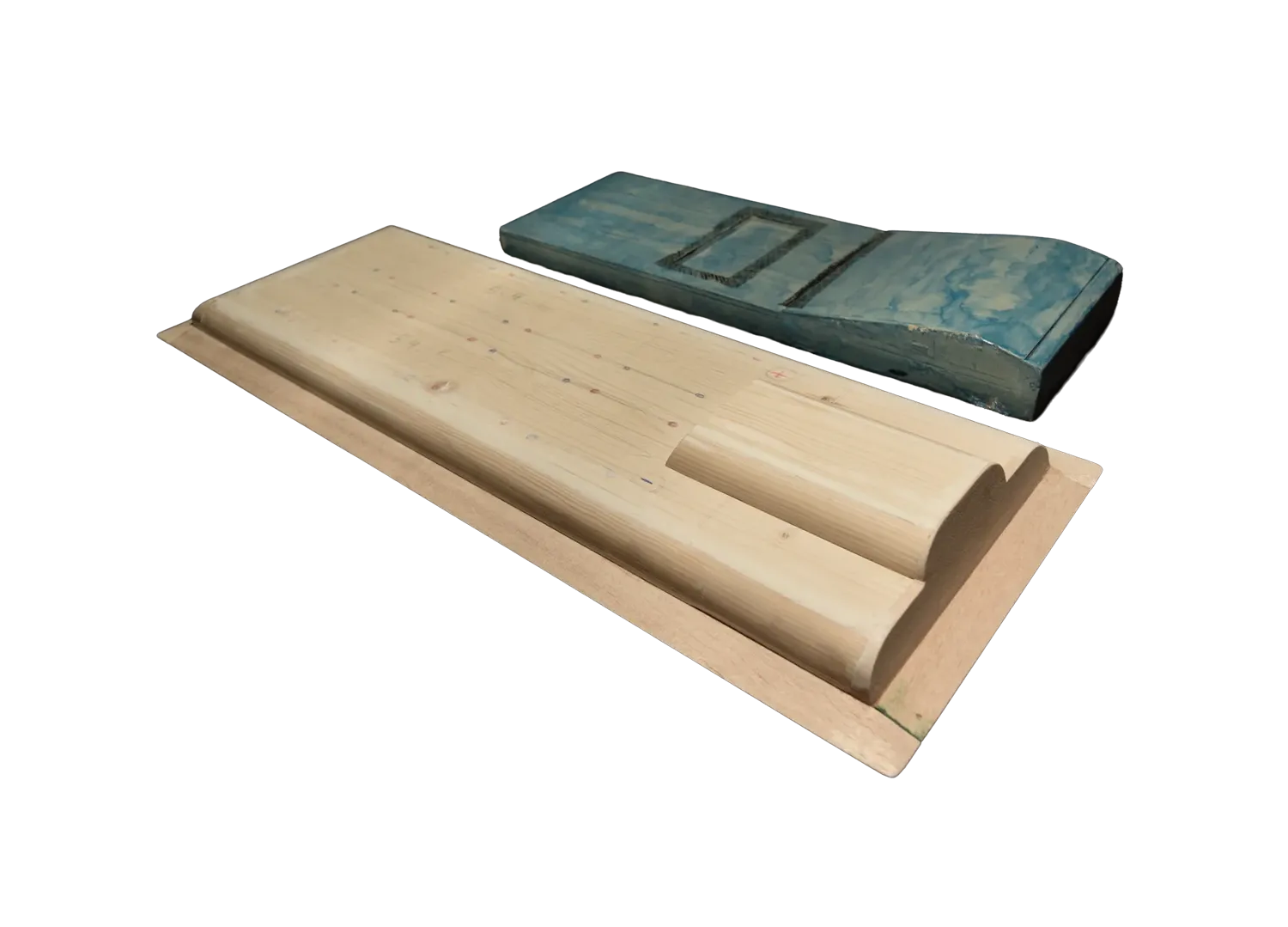

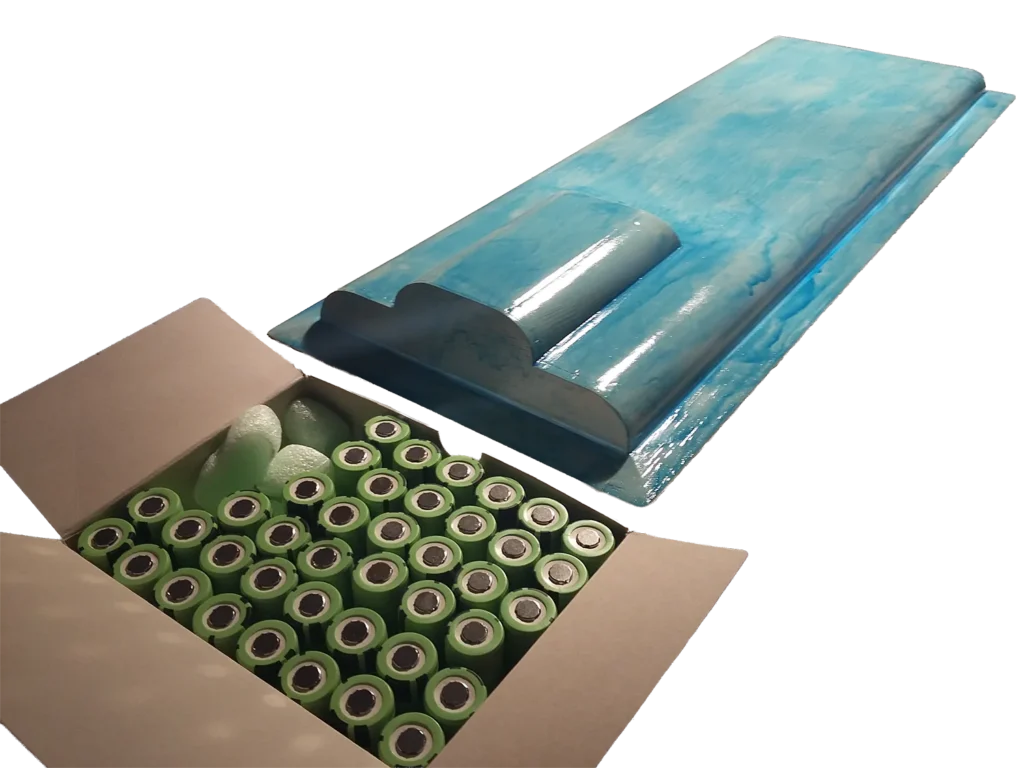

The first version was designed to house 32 NCR-18650PF battery cells and Benjamin Vedder’s VESC brushless controller. A cover in the middle of the housing provided access to the connections of the two-part battery system. Due to a lack of experience, I made an undesirable design choice regarding the 90° angle at the transition from the housing to the lip, which was intended for attachment to the longboard itself. Despite the vacuum, the fiberglass fabric was not completely pressed into the rectangular shape, which was certainly also due to the use of inflexible garbage bags instead of vacuum bags. Not ideal, the finished housing still fulfills its purpose years later.

Timelapse of the final step

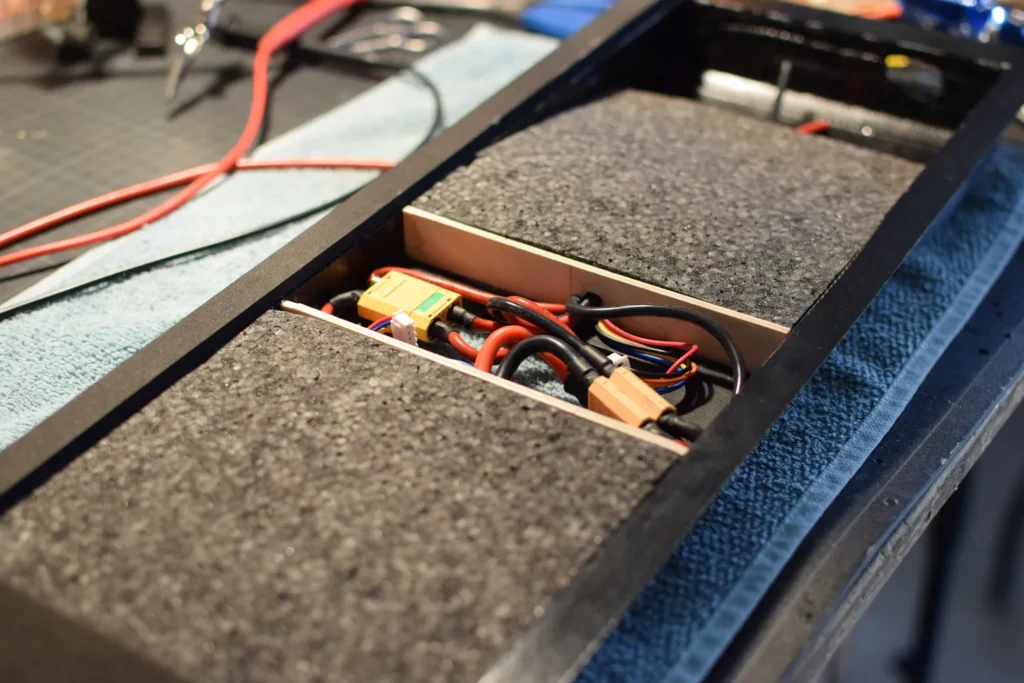

After applying various layers of epoxy-impregnated fiberglass fabric to the mold and placing the release film and breather cloth (kitchen towels) on top, the entire mold with its layers is placed in an airtight bag. After activating the vacuum pump, I assist the molding process by pressing the fabric layers into the aforementioned right angle of the mold. The black dots visible in the time-lapse video represent excess resin that is pressed through the release film into the breather cloth. This process ensures a high fiber density in the finished part and high strength with the lowest possible weight. Imagine the quality that could be achieved if professional equipment had been used instead of conventional kitchen utensils like a garbage bag, kitchen towels and a steel whool pad…

The first finished composite casing:

Bigger and better – Version II:

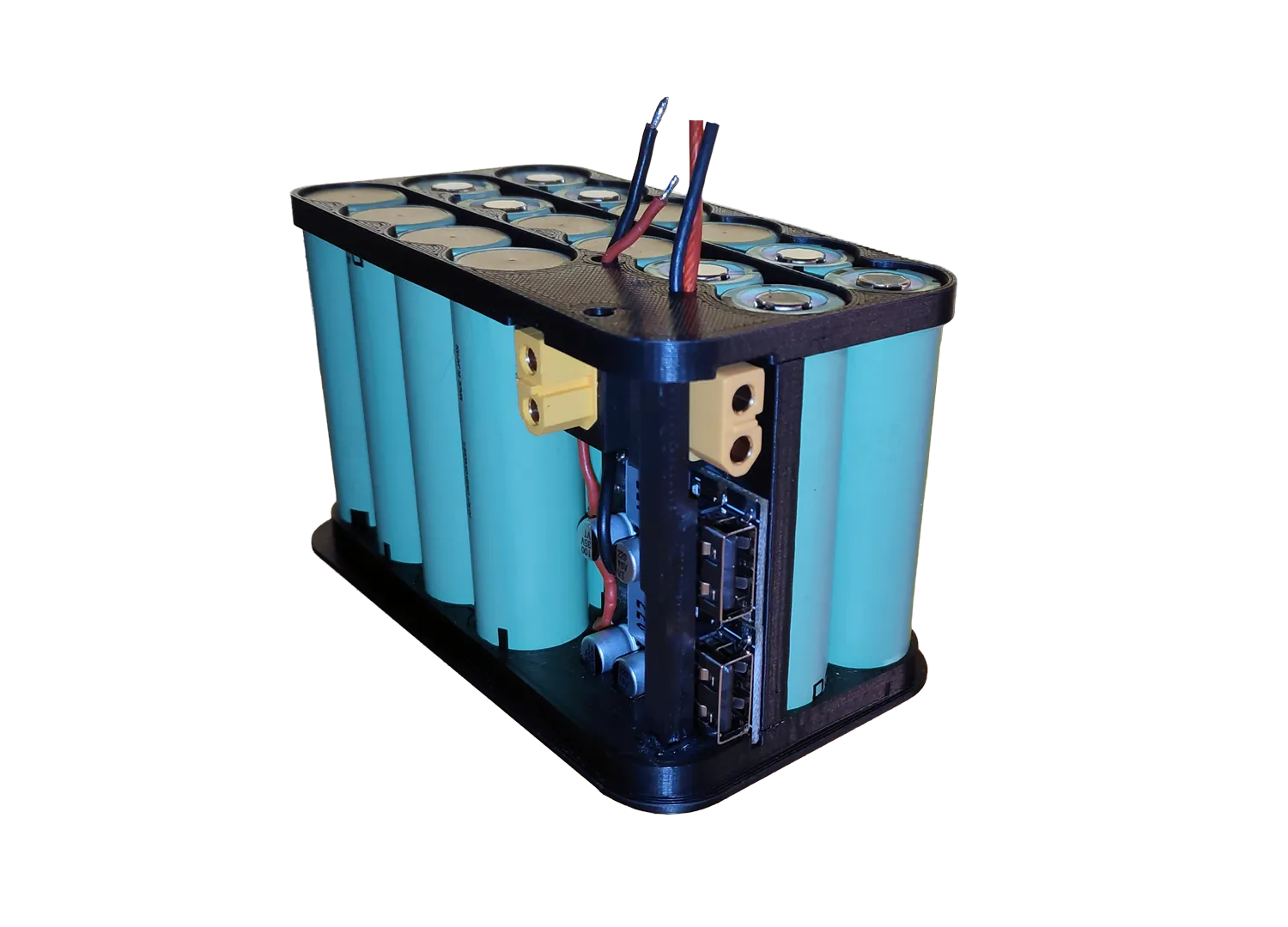

The desire to increase the speed and range of my electric longboard beyond its current limits led me to develop a second battery pack. The new 4p10s battery upped the maximum speed to a breathtaking 50 km/h and the range to well over 30 km. This measure was necessary in order to be able to overtake racing cyclists and treat myself to that certain thrill on some days. Of course, the new configuration no longer fit into the old housing, and I was also keen to incorporate the experience gained from the first prototype into a second, improved version.

Always optimize!

The new design underwent fundamental changes: a battery management system was integrated, and the built-in balancer allowed the longboard to be “refueled” with a small, commercially available charger. The battery itself was designed in two halves as separate units that were no longer permanently mounted to the housing and could therefore be replaced. They are pressed from the housing to the underside of the longboard, all in a sandwich construction, so to speak. Avoiding right angles in many places on the housing ensured a cleaner finish and a professional look. The use of heavy fabric increased the mechanical stability of the construction. Ventilation openings that could be closed in the rain allowed for better thermal management of the brushless controller, which was pushed to its performance limits in this version.

Decoupling

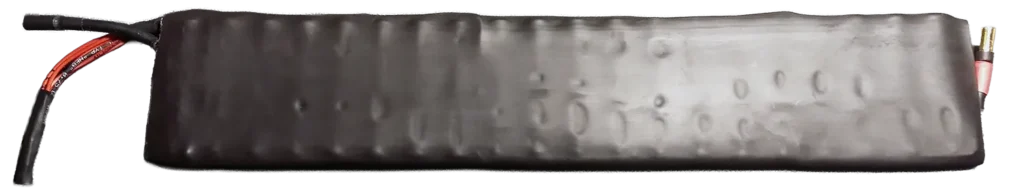

The batteries were attached to the housing with a long strip of Velcro tape. To reduce the impact of strong vibrations on the electronic components and battery during operation, the housing and battery was decoupled from the deck of the longboard using a 5 mm thick strip of neoprene. The whole assembly was then attached with rubber-mounted screws.

Below you can see one half of the battery:

Completed E-board with 1.6 kW system power